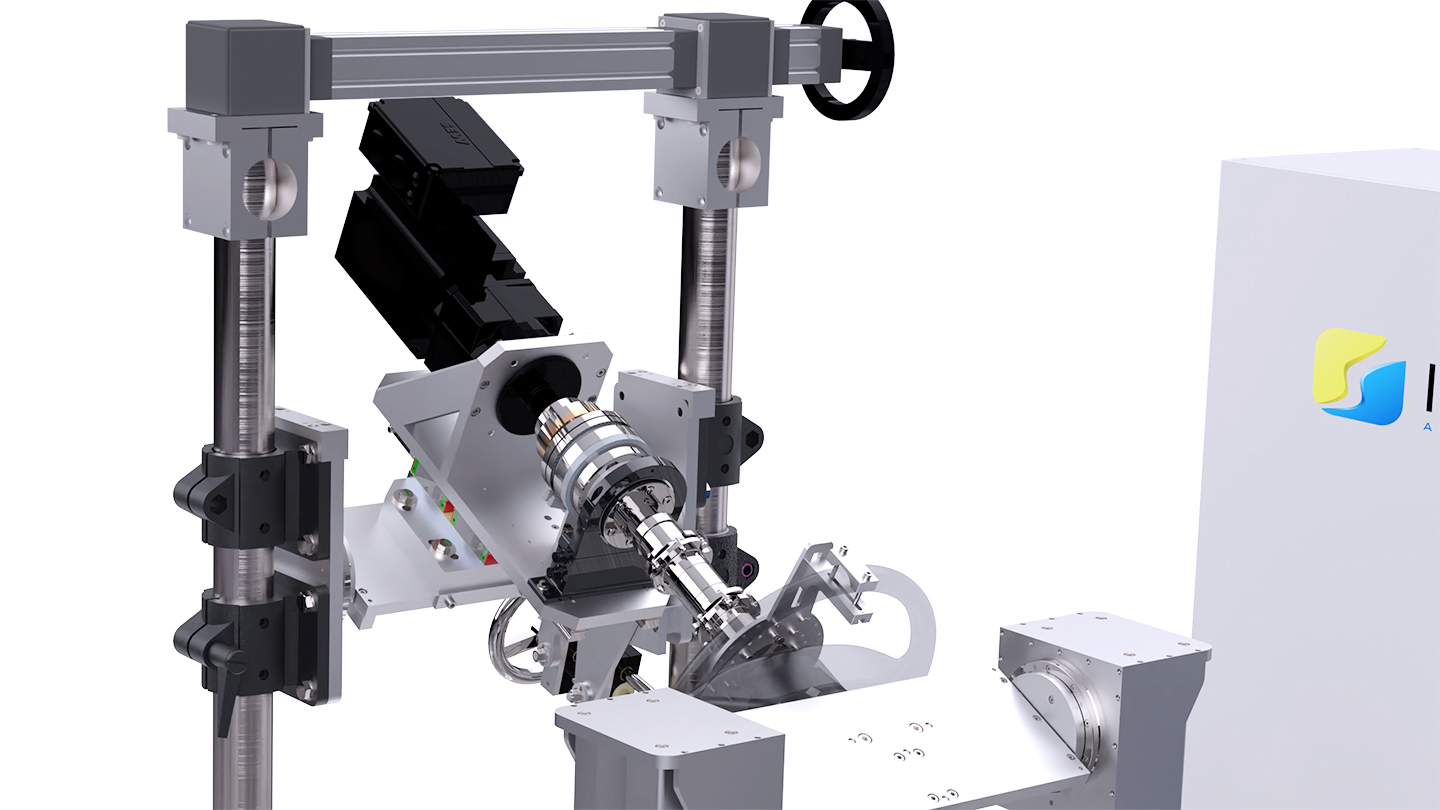

The Steering-in-the-Loop test bench enables comprehensive tests of steering systems as a real component in a closed loop. Using a highly dynamic steering wheel motor, gear rack force actuators as well as force and motion control on the gear rack, all types of steering systems can be tested easily and flexibly on the test bench.

Functions

- Electric column adjustment

- Steer-by-angle and steer-by-torque steering modes on the steering wheel

- Driver-in-the-Loop platform

- Vertically adjustable steering rod forces

- Easy setup and orientation of steering wheel and steering robot

- Multi-domain HIL extension in combination with suspension and ADAS ECUs in real time

- Force sensors, torque sensors and current sensors for all measurements

Application areas

- Test of automated driving functions with easy integration of electrical steering system components

- Optimization of control units with function, performance and variance tests

- Implementing homologation tests with early release maneuvers

- Performing virtual benchmarks

- Tests and steering functions in the fields of vehicle dynamics and ADAS

- Investigation of all-wheel/rear wheel steering with up to 4 linear actuators

- Steer-by-Wire applications

- Manual steering input for any driving scenario

- Extensive system optimization for active systems e.g. MBS suspension model, tires and vehicle

Your benefits at a glance

Short latencies and compensation

hardware, software and networking concept from a single source for closed-loop maneuvers

Simplicity

Easily perform complex closed-loop maneuvers

Significant test results

Optimal force resolution up to the physical limits

Fast and precise control

Use of two electric linear actuators

Extensive test automation

Apply complete test catalogs (ISO steering maneuvers, Euro NCAP, customer-specific tests)

EtherCAT communication with 2kHz

Technical data

- Peak force (each) – 20 KN

- Mean force (each) – 12 KN

- Active width of actuator – - 200 mm

- Maximum velocity – +- 1m/s

- Peak torque – 120 Nm

- Mean torque – 50 Nm

- Max. steering wheel velocity – 1800 deg/s

- Real-time configuration for the Steering-in-the-Loop test bench

- Expandable with multi-domain HIL platform including the integration of chassis and ADAS ECUs

Hands Off Clutch

The new clutch system enables the decoupling of the force transmission of the steering actuator. Therefore, critical hands-on/hands-off transition maneuvers can be validated in fully deterministic and reproducible applications. Driving functions for fully automated vehicles can therefore be tested, and steering system test benches can be expanded by the functionality for tests according to ISO 26262.

Driver-in-the-Loop Platform

- Big screens for visualization

- Adjustable to the real driving position

- Access to all CarMaker GUIs from the driver’s seat

- Fast and easy setup

- SoundMaker for realistic vehicle noises

- Reduced frame size and robust construction

- Safety of the human driver